Background

In recent years, smart watches are not only a tool for time, but also become multi-functional integrated devices such as health monitoring, exercise tracking and smart notifications. With increasing health awareness, consumers’ demand for health management functions such as heart rate monitoring, sleep analysis, and exercise recording has surged, driving the rapid growth of the market. In addition, the design of smart watches is becoming more and more fashionable, with personalized customization functions to meet the aesthetic and use needs of different users. More and more brands are launching smartwatches with high-performance processors, high-resolution displays and long battery life, further enhancing the user experience. At the same time, market competition is also increasing, and multiple brands and emerging companies have poured in to promote product diversification. Manufacturers need to respond quickly to market changes and introduce innovative products to meet the diverse needs of consumers. This makes production efficiency and product quality control more important.

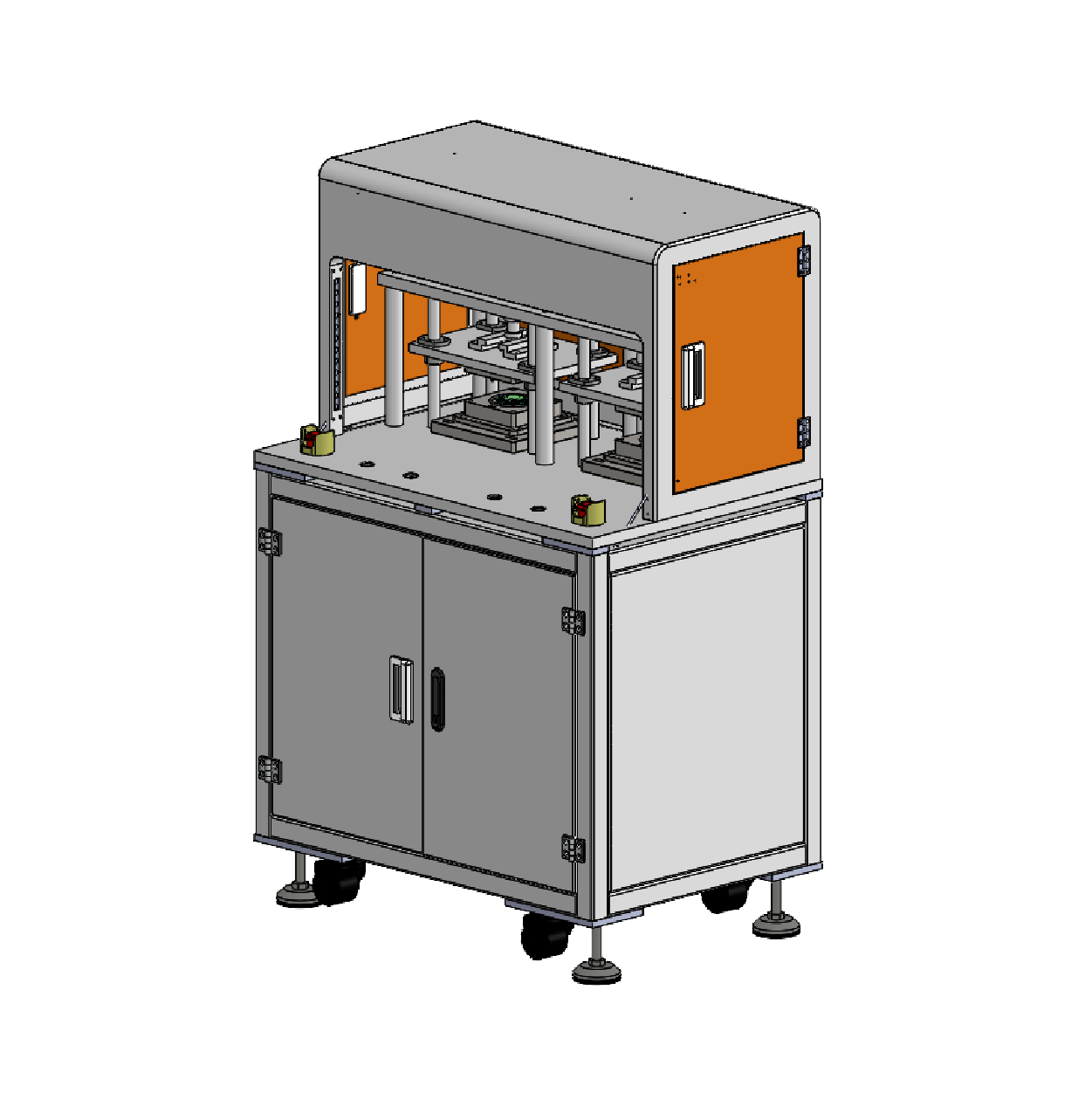

Airtight test equipment

Airtight testing equipment is specially designed to test the airtightness of products to ensure that no leakage occurs during use. Through precise air tightness detection technology, the equipment can quickly identify the sealing performance of products under different pressure and temperature conditions, ensuring that it meets industry standards and customer requirements.

Underlying Parameter

| Working pressure (M Pa) | >0.5Mpa |

| Size(mm) | 810x550x1270 |

| Weight(kg) | 300 |

| Control System | PLC |

| UPH | 60 |

| Yield(%) | 99 |

| Operation rate (%) | 95 |

| Working Voltage(AC) | 220V |

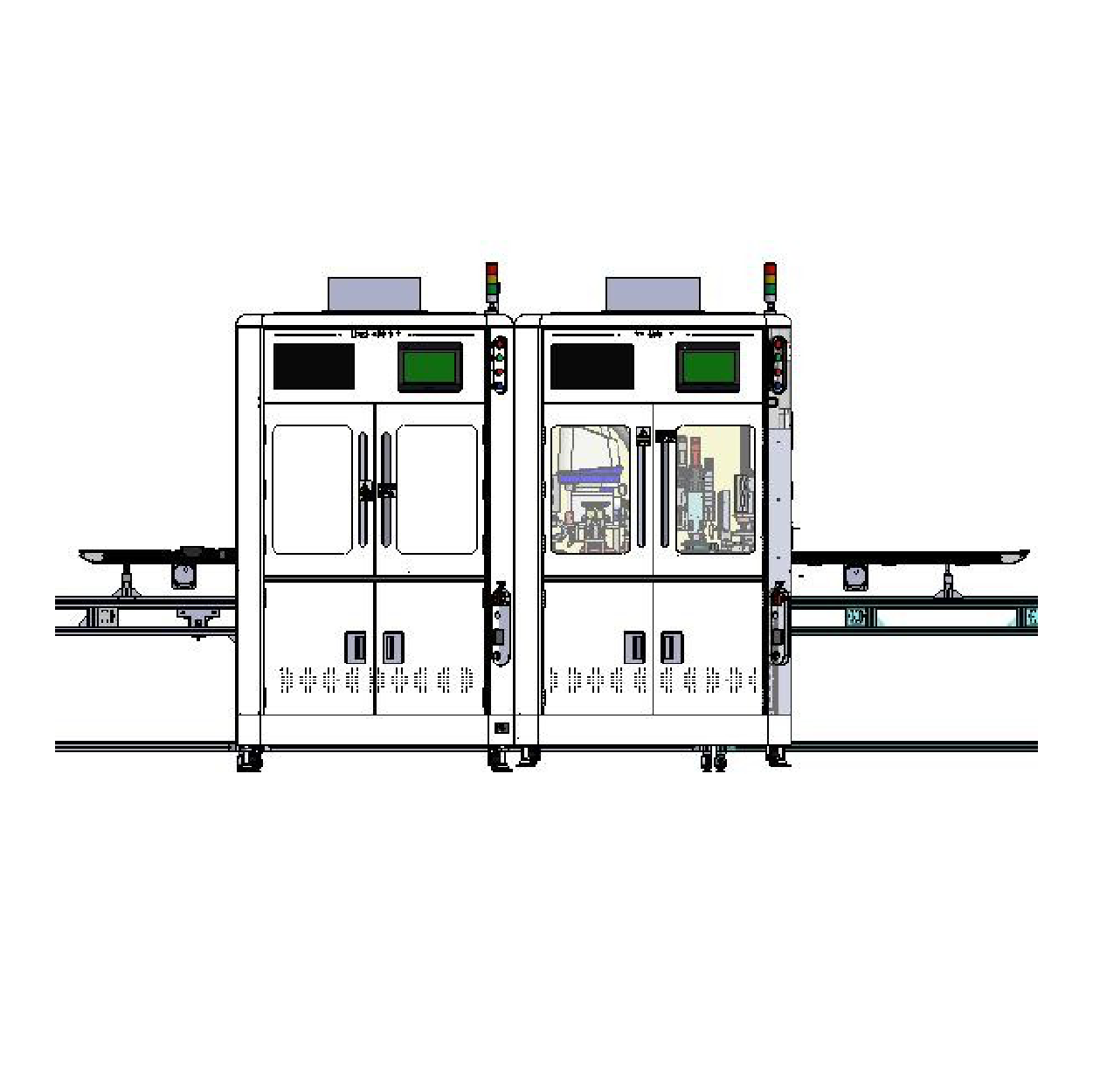

Automatic foam attachment equipment

The automatic foam attachment equipment is designed to improve production efficiency and attachment accuracy, and uses industrial CCD feeding and mounting positioning system to ensure high precision and efficient performance. The device is equipped with a 4-axis manipulator to achieve fast take-up and attachment, with good compatibility and flexibility to adapt to the needs of different products. Its multistation assembly line design allows the product to be picked up and placed without stopping, significantly improving the operating efficiency of the machine. The equipment not only realizes the automatic foam paste and pressure retention function, but also is equipped with CCD detection system to ensure the quality of each attachment link. Qualified products will be automatically placed into the Tray tray, further optimizing the production process, reducing manual intervention, and improving the intelligent level of the overall production line.

Underlying Parameter

| Working Air Pressure(M Pa) | ≥0.6 |

| Size(mm) | 3630* 900* 2080 |

| Weight(kg) | 600 |

| Number of stations | One station |

| CT | 600pcs/h |

| Working Voltage(AC) | 220V |

Automatic assembly of gasket equipment

The automatic washer assembly equipment is designed to improve the efficiency and accuracy of washer assembly, and uses industrial CCD feeding and mounting positioning technology to ensure high precision and efficient work flow. The unit is equipped with a 4-axis manipulator for quick take-up and attachment, with excellent compatibility and flexibility to accommodate different types of gaskets. The drive system uses servo motors, stepper motors and linear modules to ensure stable operation and precise motion control. Gasket’s feed is designed by Feida for efficient automatic feed, further improving the overall efficiency of the production line. The equipment not only automatically assembles Gasket and maintains pressure, but also has a CCD inspection system to ensure quality at every stage of assembly. The qualified HSG with Carrier will be automatically transported to the blanking flow line and smoothly transferred to the next station.

Underlying Parameter

| Working Air Pressure(M Pa) | ≥0.6 |

| Size(mm) | 1500* 1200* 2200 |

| Weight(kg) | 1100 |

| Number of stations | Four station |

| CT | 3.5s /pcs |

| Working Voltage(AC) | 220V |

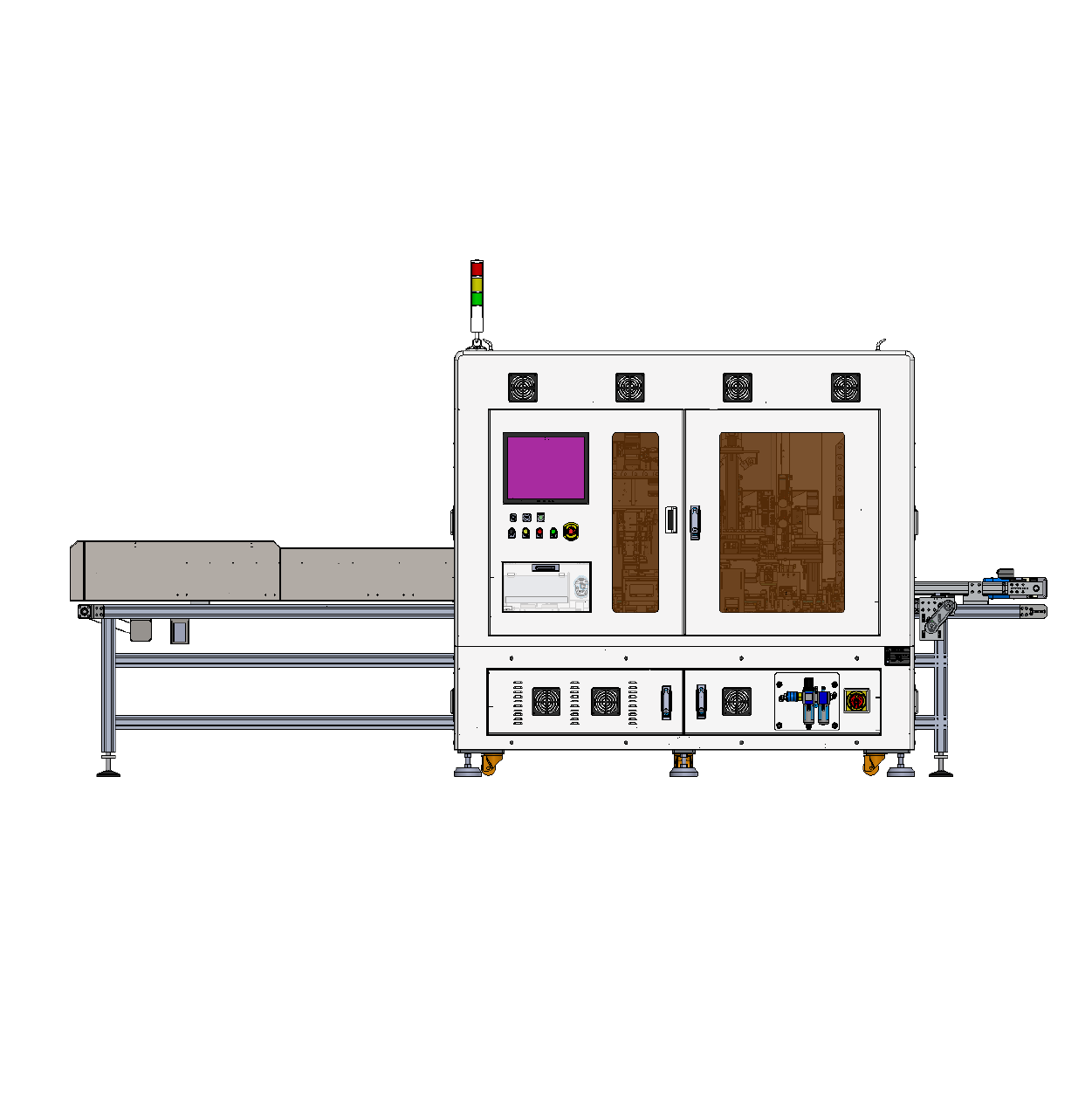

Automatic sealing equipment

The automatic seal equipment is designed for efficient and accurate attachment processes and uses Feida feeding systems to ensure fast feed and precise discharge positions. The equipment is equipped with backflow loading stage step transplanting, double stations can realize synchronous operation, greatly improving the production efficiency. The equipment uses industrial CCD for positioning and guidance to ensure high precision and high efficiency. After the product flows in, the system automatically detects the product information, and Feida provides the corresponding Seal according to the demand. The labeling module quickly takes materials and attaches to the inside of the box under the guidance of CCD, then the clamshell module turns over the upper cover, and the CCD accurately locates the position of the bottom box, guides the cover box module to complete the closing action of the upper cover and the bottom box, and smoothen the seal. After holding the pressure, the reinspection CCD will detect the adhesion effect, if it is qualified, it will automatically cut to the main water line, if it is not qualified, it will be transferred to the NG flow line for processing.

Underlying Parameter

| Size(mm) | 2000* 1950* 1850 |

| Weight(kg) | 2000 |

| Yield(%) | |

| CT | 450pcs/h |

| Working Voltage(AC) | 220V |

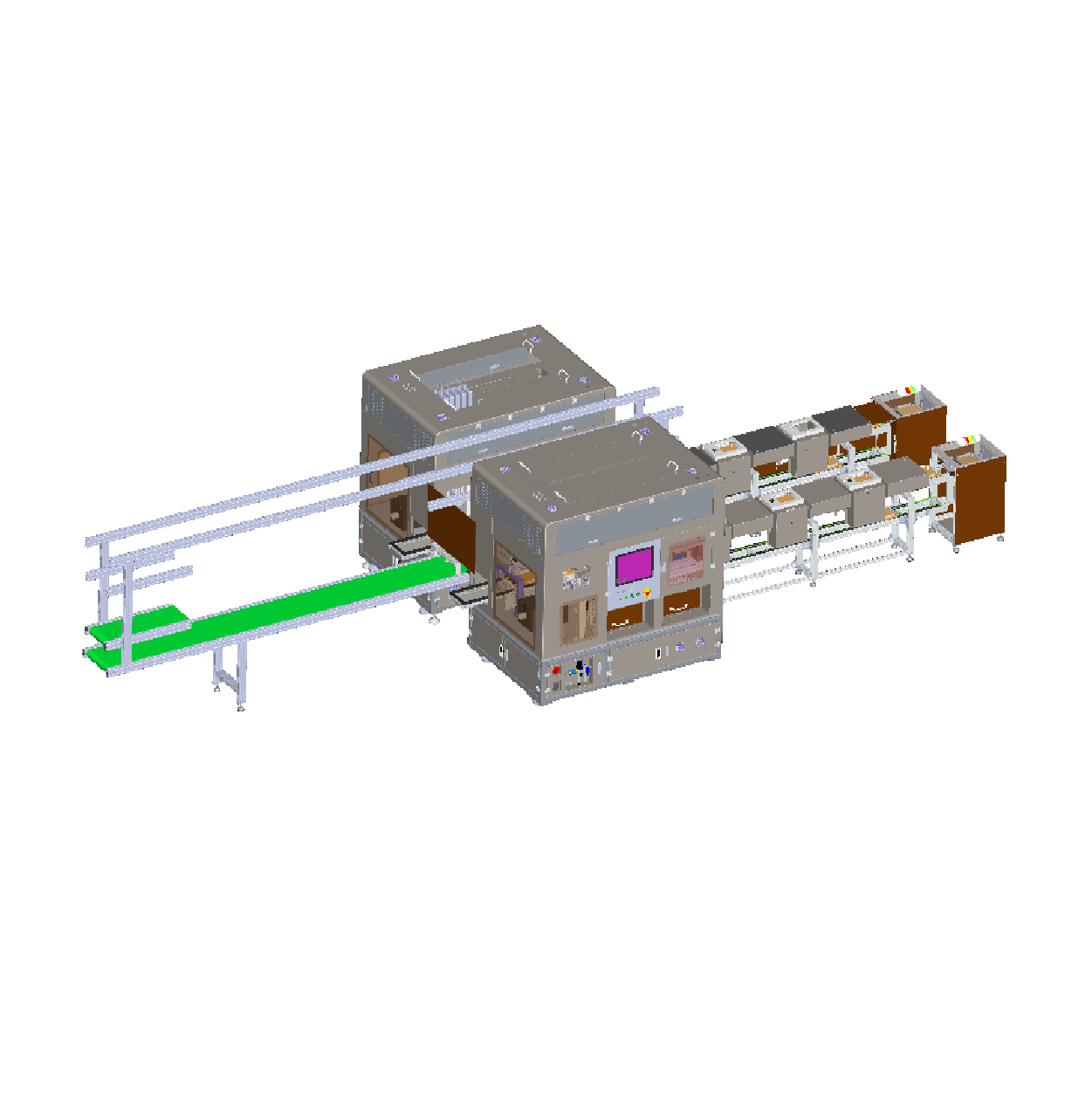

FCM assembly and cleaning equipment

The FCM Assembly and cleaning equipment is designed to increase assembly accuracy and cleaning efficiency, and its main function is to automatically assemble FCM components into brackets. The equipment is equipped with an advanced inspection system that can monitor and automatically detect the assembly effect in real time, ensuring the correct position and stability of each component. In addition, the device has the ability to clean the FCM, ensuring that the components meet high standards of cleaning before assembly.

Underlying Parameter

| Working Air Pressure(M Pa) | 0.5 |

| UPH | 680 |

| Size(mm) | 3500x4800x1850 |

| Weight(kg) | 300 |

| Yield(%) | 99 |

| Control System | h5u |

| CT | 10s |

| Working Voltage(AC) | 220V |

Contact Us

For more information about products and solutions, please leave a message.