Background

Today, with the rapid development of digitization and information technology, laptop computer has become an indispensable tool in People’s Daily life and work. Since the 1980s, the pen industry has undergone a major transformation from heavy portable devices to thin and efficient products, gradually meeting the diversified needs of business, education, entertainment and so on. As technology continues to advance, the performance, design and functionality of laptops continue to evolve, especially driven by intelligence and mobile Internet, ushering in new development opportunities for the industry.

In recent years, especially as the COVID-19 pandemic has accelerated the popularity of telecommuting and online learning, the market demand for laptops has surged, prompting brands to innovate to meet users’ expectations for high performance, portability and versatility. At the same time, the promotion of environmental awareness has also promoted the transformation of the industry to sustainable development. In the future, the pen industry will continue to seek breakthroughs in the fierce market competition, shape more intelligent, environmentally friendly and efficient products, and provide users with a better experience.

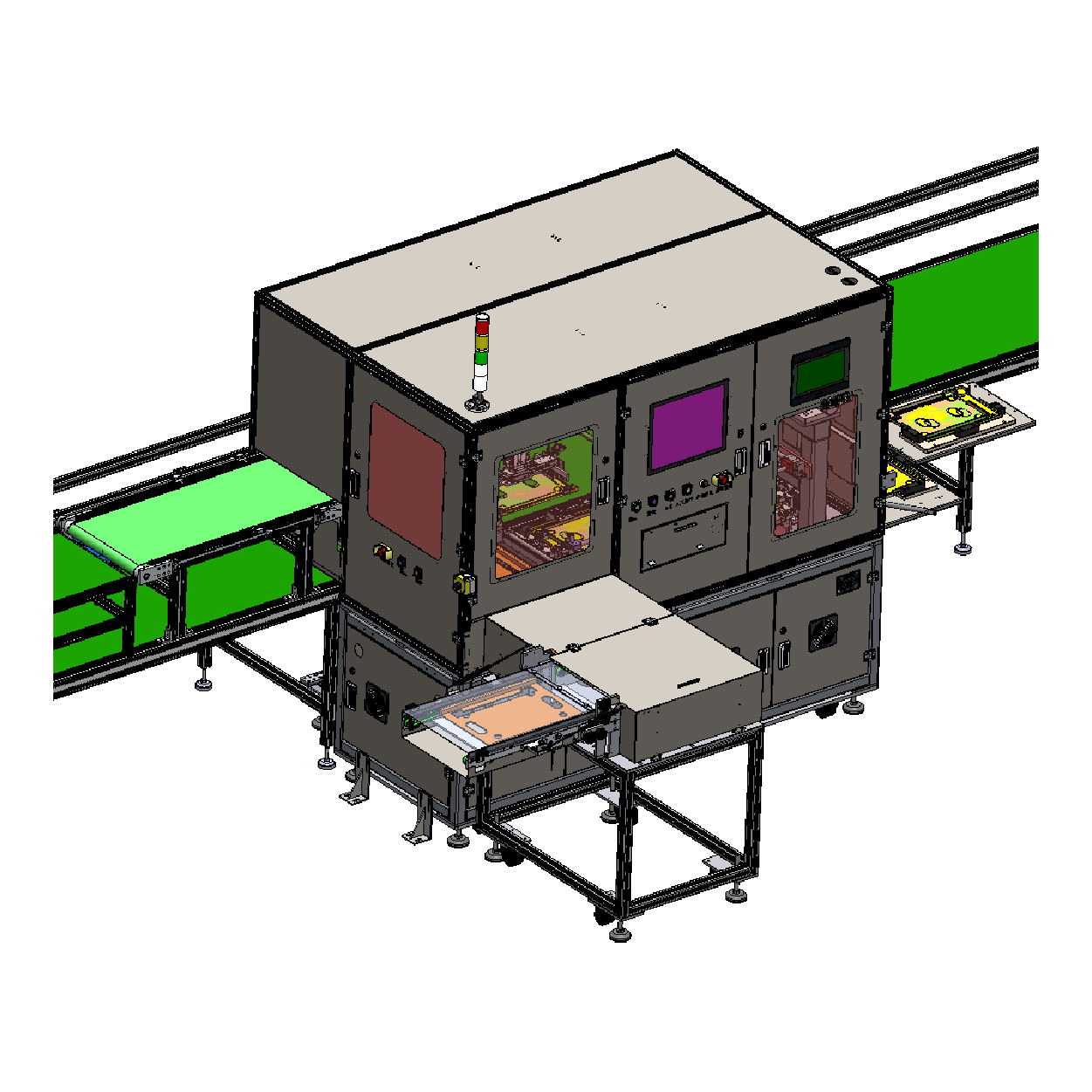

Inline computer impedance test equipment

Inline computer impedance test equipment with advanced automatic plug and unplug function for efficient and accurate testing. At the same time, the equipment is equipped with an automatic code scanning system to ensure the accuracy and traceability of every operation. Its automatic loading and unloading function greatly improves production efficiency, reduces manual intervention, and ensures smooth production processes. If there are unqualified products, the equipment will immediately issue NG alarm, effectively ensure product quality, and improve the overall production management level.

Underlying Parameter

| Working pressure (M Pa) | 0.5 |

| Size(mm) | 2500×1735×1800 |

| Weight(kg) | 1000 |

| Control System | PLC |

| UPH | 250 |

| Yield(%) | 99 |

| CT | 14.5 |

| Working Voltage(AC) | 220V |

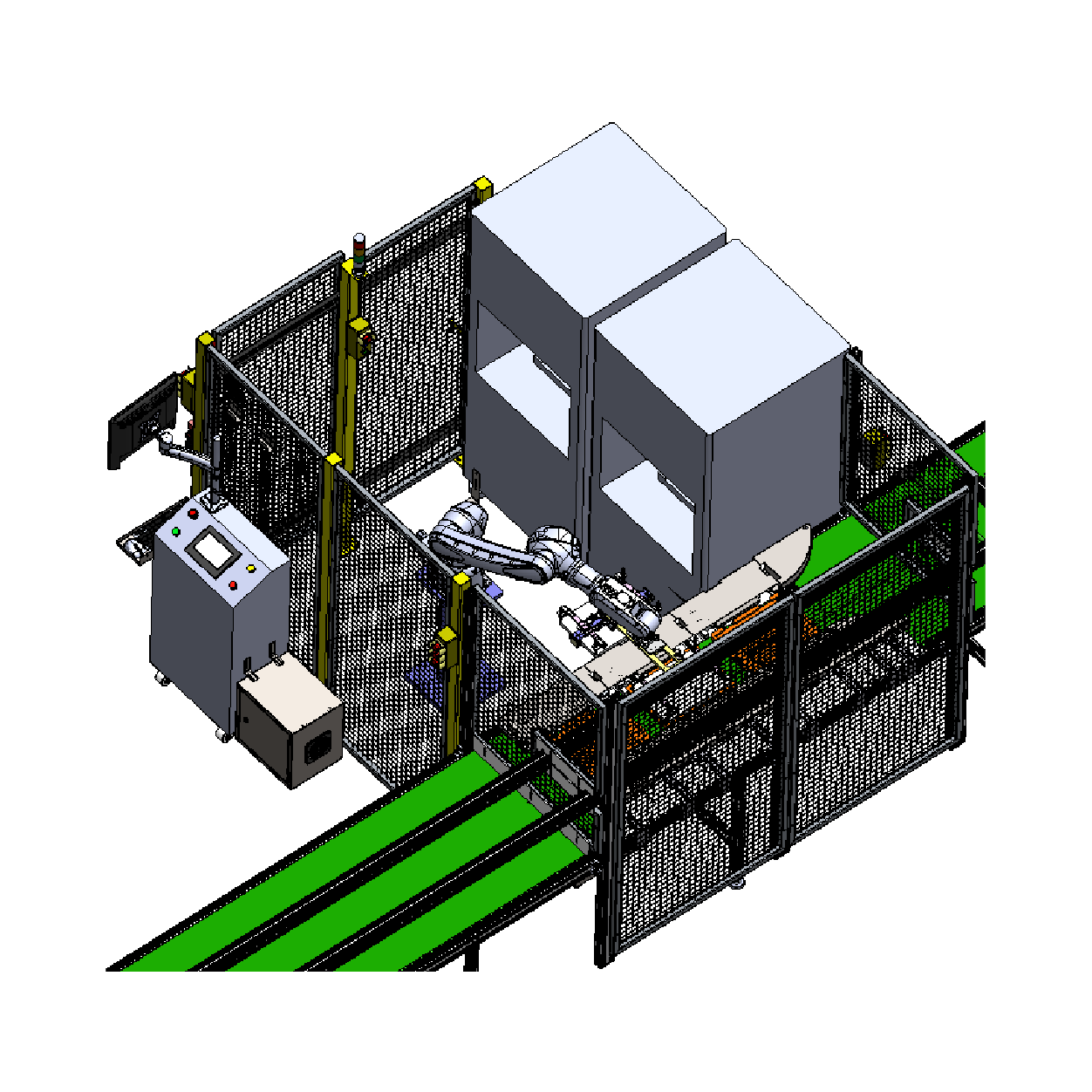

Backlight pressing manipulator equipment

The backlight pressing robot equipment has an advanced flow path automatic material separation function, which can efficiently and accurately distribute materials to various production links to improve work efficiency. At the same time, the equipment is equipped with an automatic loading and unloading system, which greatly reduces the need for manual operation and ensures the smooth and safe production process. In terms of quality management, the equipment is equipped with an instant NG alarm system, which can quickly identify unqualified products and issue alarms, effectively maintain product quality, and improve the overall production efficiency and reliability.

Underlying Parameter

| Working Air Pressure(M Pa) | 0.5 |

| Size(mm) | 1950x1600x1800 |

| Weight(kg) | 240 |

| Control System | PLC |

| UPH | 250 |

| Yield(%) | 100 |

| CT | 14.5s/pcs |

| Working Voltage(AC) | 220V |

Contact Us

For more information about products and solutions, please leave a message.