Background

In the era of accelerated digital transformation, servers, as the core of information technology infrastructure, carry the data processing and storage needs of enterprises. With the rise of technologies such as cloud computing, big data and artificial intelligence, the server market is experiencing unprecedented growth opportunities. However, in the face of increasing performance requirements and increasingly complex assembly processes, enterprises urgently need to improve production efficiency and product quality. We provide innovative solutions for the server sector of the 3C industry, optimizing assembly and testing processes through intelligent technology to meet the market’s urgent demand for efficient and reliable servers and help enterprises stay ahead of the fierce competition.

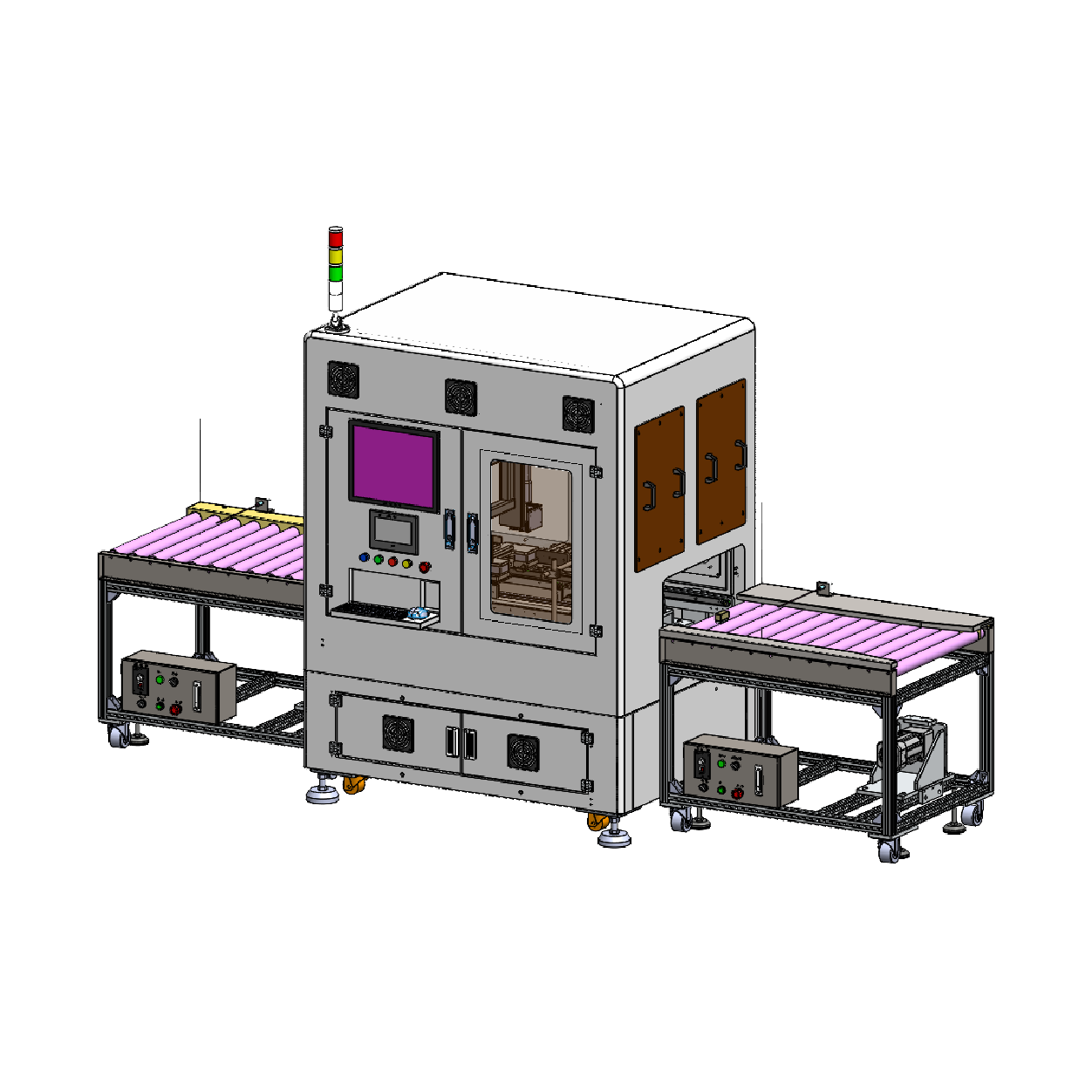

The PSU is assembled into the chassis

The PSU Assembly to Chassis feature focuses on the precise installation of the power supply unit (PSU) into the chassis, along with inspection systems to ensure that assembly accuracy meets industry standards. This function not only improves the assembly efficiency, but also ensures the close combination of the power supply and the chassis through the real-time monitoring and feedback mechanism, reducing the risk of possible faults in subsequent use, and improving the overall stability and reliability of the device.

Underlying Parameter

| Working pressure (M Pa) | 0.5~0.6 |

| Size(mm) | 3250x1000x1850 |

| Weight(kg) | |

| Control System | PLC |

| UPH | 112pcs/h |

| Yield(%) | |

| CT | |

| Working Voltage(AC) | 220V |

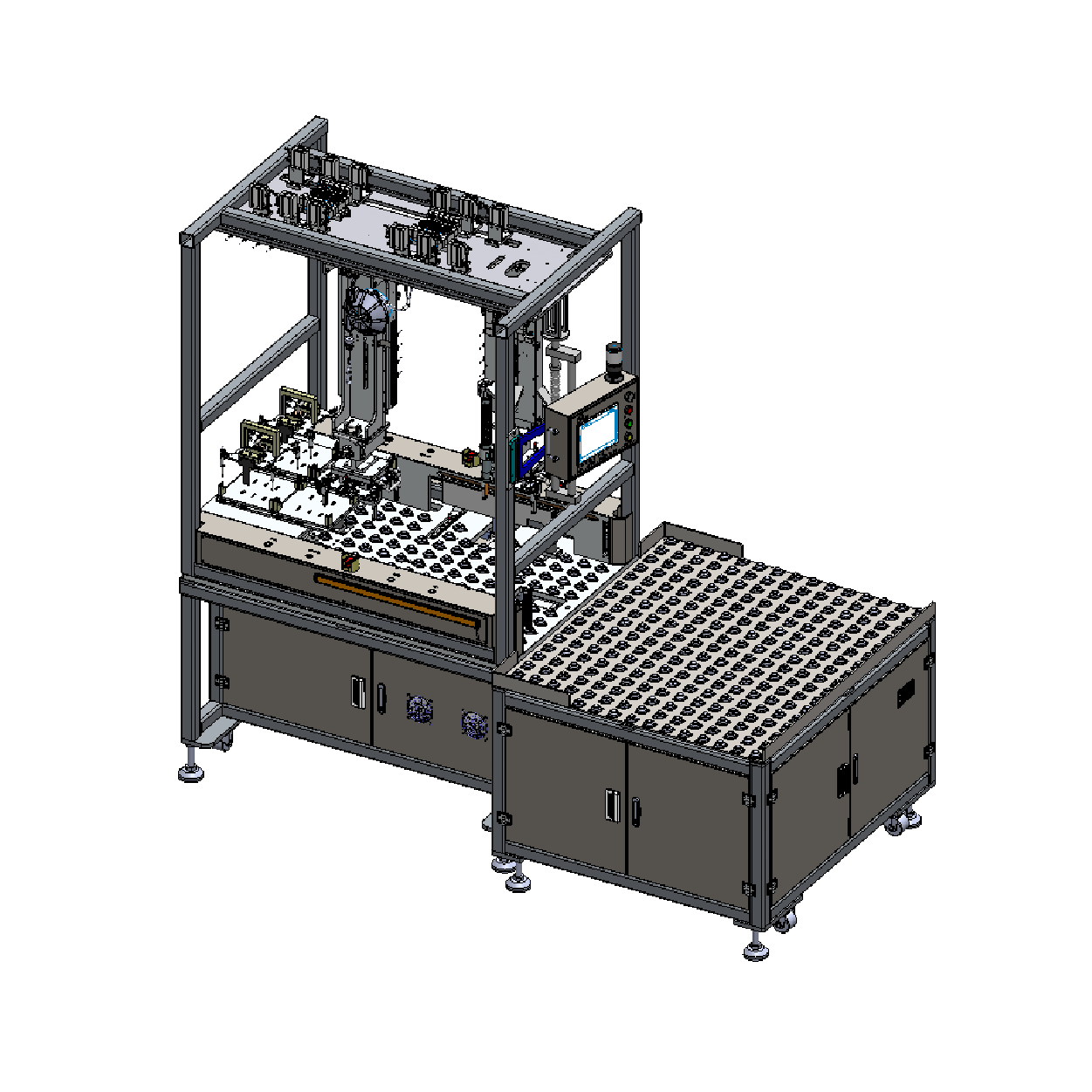

TM SUB is assembled into the chassis

The TM SUB Assembly to Chassis function focuses on the precise installation of TM SUB modules into the chassis, ensuring perfect fit and stability between components. This feature not only improves assembly efficiency, but also reduces the risk of errors during assembly through optimized design and processes, ensuring high quality and reliability of the final product.

Underlying Parameter

| Working Air Pressure(M Pa) | 0.5~0.6 |

| Size(mm) | 2200x1100x2050 |

| Weight(kg) | |

| Control System | PLC |

| UPH | |

| Yield(%) | |

| CT | |

| Working Voltage(AC) | 220V |

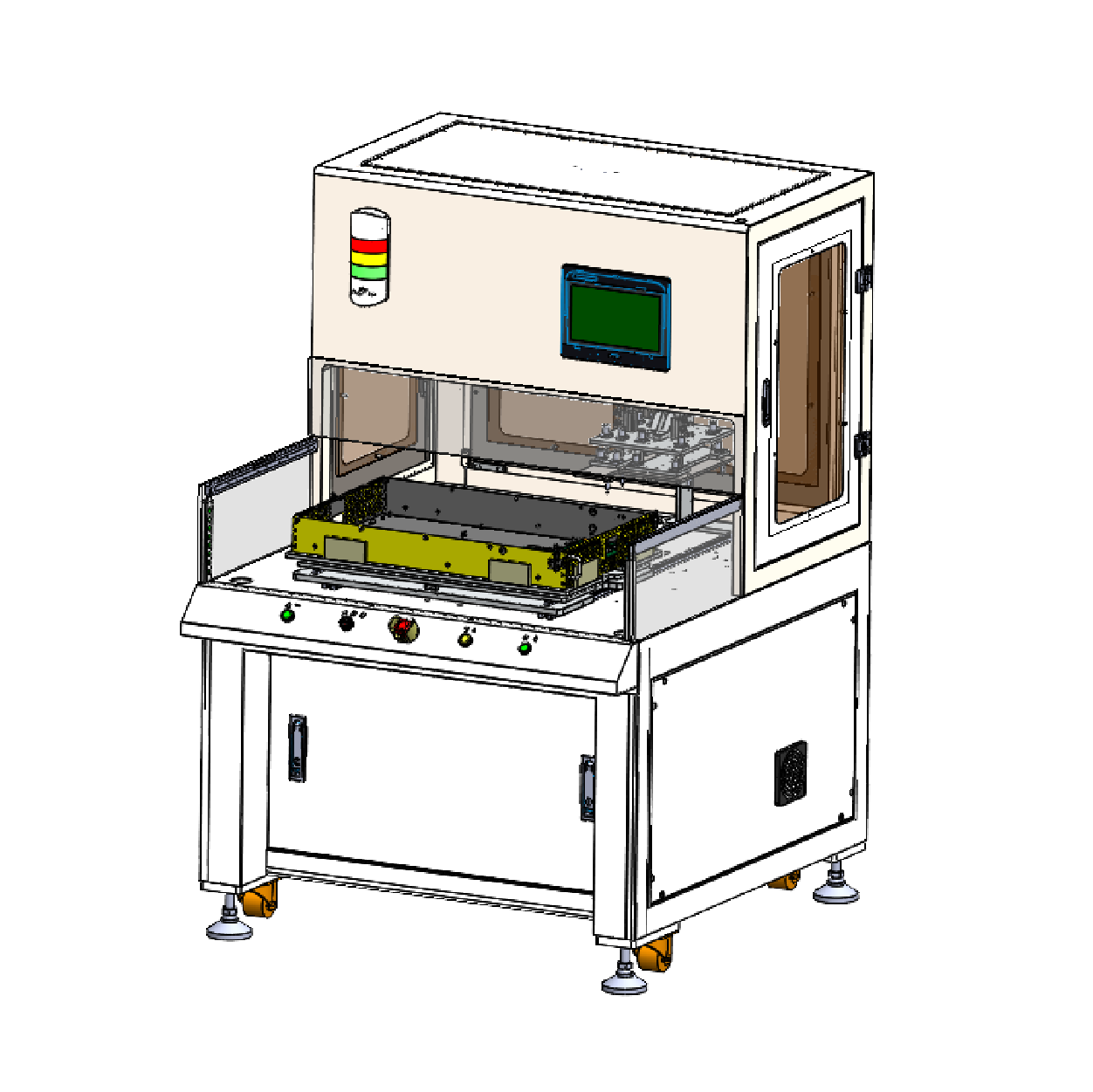

NIC removal

The NIC removal feature focuses on removing network interface cards (nics) efficiently and safely, ensuring that no damage is caused to other components during removal. This feature combines precise operating tools and processes designed to improve disassembly efficiency while reducing manual error and ensuring smooth maintenance and upgrades.

Underlying Parameter

| Working Air Pressure(M Pa) | 0.5~0.6 |

| Size(mm) | 1100x1200x1700 |

| Weight(kg) | |

| Control System | PLC |

| UPH | 257pcs/h |

| Yield(%) | |

| CT | |

| Working Voltage(AC) | 220V |

Contact Us

For more information about products and solutions, please leave a message.