Background

In the context of today’s rapid development of technology, the virtual reality (VR) industry is experiencing an unprecedented boom. With the advancement of hardware technology and the richness of content ecology, VR has gradually penetrated from the early laboratory application to many fields such as entertainment, education, medical care and training. The growing consumer demand for immersive experiences is driving the widespread adoption of VR devices. At the same time, the VR industry is facing enormous competitive pressure, and manufacturers need to achieve greater efficiency and flexibility in product design and production processes to meet the increasingly diverse needs of the market. This requires enterprises to not only improve the quality of production, but also shorten the time to market of products in order to quickly respond to changes in consumers.

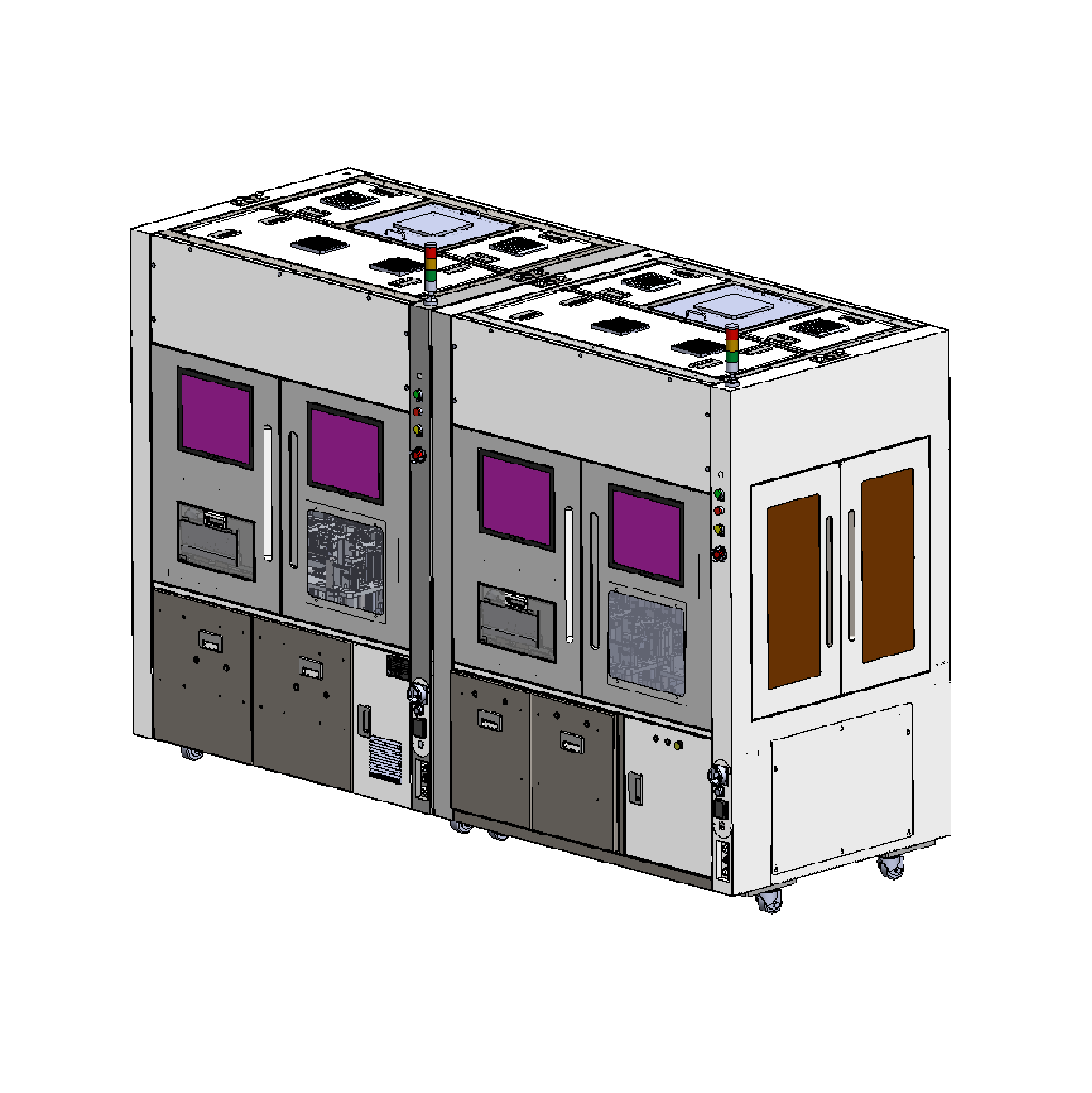

Encoder bend – assemble – dispense

Encoder bending, assembling and dispensing equipment integrates automatic bending, dispensing, assembly and inspection functions to enhance the automation level of the production line. The equipment adopts high-precision two-component screw valve, combined with external liquid cooling temperature control system, to ensure the temperature stability during the dispensing process, to achieve the best bonding effect. At the same time, the 3D camera guides the glue dispensing to ensure that the glue is accurately applied. The equipment is equipped with 3D camera for rubber path detection, and realizes camera reinspection and assembly, constructing a complete closed-loop system, effectively improving the yield of the product and the overall production efficiency. This design not only ensures high precision and high reliability, but also makes the production process more intelligent.

Underlying Parameter

| Working pressure (M Pa) | ≥0.6 |

| Size(mm) | 3000*1100*1850 |

| Weight(kg) | 1600 |

| Control System | PC |

| UPH | 200 |

| Yield(%) | 99.99% |

| Operation rate (%) | 98% |

| Working Voltage(AC) | 5KW |

OMJB Labeling – Bending equipment

The OMJB labeling and bending equipment integrates PSA (pressure sensitive adhesive) automatic attaching, detecting and bending functions to increase productivity and accuracy. The device utilizes an advanced linear motor module to achieve precise attachment of a wide range of PSA heights, ensuring high quality and consistency at every labeling step. At the same time, the equipment has automatic detection function, real-time monitoring of the attaching effect, timely correction of deviations, to ensure that the labeling is perfect. The overall design makes the labeling and bending process efficient and smooth, greatly improves the automation level and reliability of the production line, and meets the requirements of modern manufacturing industry for high efficiency and high precision.

Underlying Parameter

| Working Air Pressure(M Pa) | ≥0.6 |

| Size(mm) | 4640*1100*1800 |

| Weight(kg) | 1800 |

| Control System | PC |

| Yield(%) | 99.99% |

| Operation rate (%) | 98% |

| UPH | 200 |

| Working Voltage(AC) | 6KW |

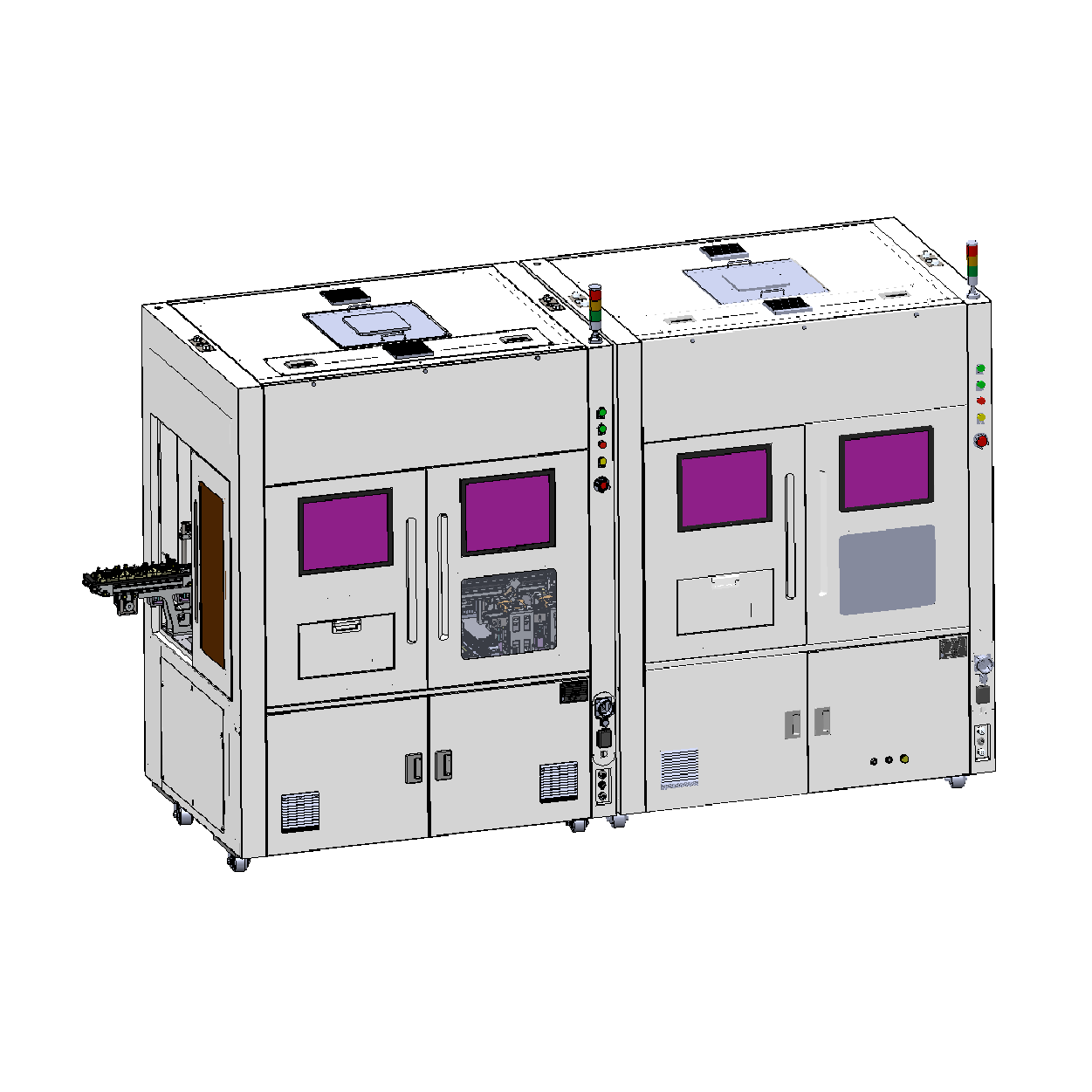

IMU bending, assembling and dispensing equipment

IMU bending, assembling and dispensing equipment is designed to increase production efficiency with automatic bending, dispensing, assembly and inspection of IMU lines. High precision two-component screw valve, coupled with external liquid cooling temperature control system, to ensure the temperature stability during the dispensing process, optimize the glue performance. The 3D camera technology guides the glue dispensing, ensures the accurate coating of the glue, and conducts the glue detection through the 3D camera, realizes the camera reinspection and assembly, and forms a closed-loop control system. This set of efficient solutions not only improves the yield of the equipment, but also enhances the intelligence and reliability of the production process to meet the high standards of modern manufacturing.

Underlying Parameter

| Working Air Pressure(M Pa) | ≥0.6 |

| Size(mm) | 3000*1100*1850 |

| Weight(kg) | 1600 |

| Control System | PC |

| UPH | 200 |

| Yield(%) | 99.99% |

| Operation rate (%) | 98% |

| Working Voltage(AC) | 6KW |

Contact Us

For more information about products and solutions, please leave a message.