Background

As the automotive industry transitions to electrification, intelligence and connectivity, consumer demand for smart cabins is increasing. This is not only reflected in the expectation of high-performance infotainment systems, but also in the pursuit of safety, comfort and personalized experiences. In recent years, the smart cabin has gradually integrated advanced sensors, artificial intelligence and big data analysis technology, making the driving experience more intelligent. For example, voice recognition, gesture control and touch interfaces make it easier for drivers to access information and control in-car functions while driving. At the same time, with the development of autonomous driving technology, the function of the intelligent cockpit is increasingly complex, from the traditional navigation and entertainment system to a comprehensive intelligent ecosystem. In addition, the smart cabin also emphasizes the interconnection with smart devices, supporting a variety of communication methods such as Bluetooth, Wi-Fi and on-board networks, making the vehicle more closely connected to the life of the user. These changes not only enhance the ride experience, but also promote the upgrading of the car manufacturing process.

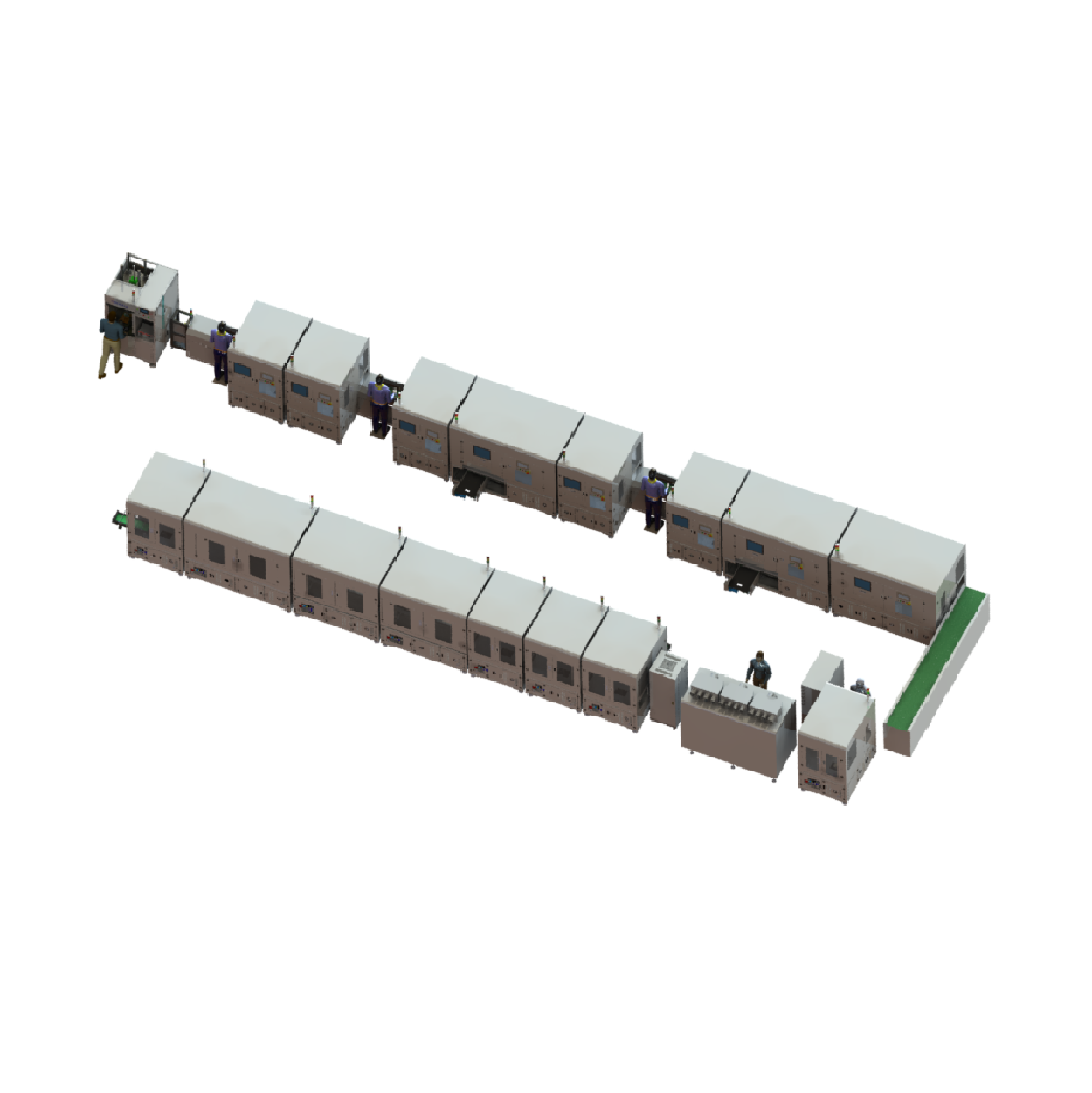

Engine system A assembly test line

Engine system A assembly test line has the dual functions of automatic assembly and testing, aiming to improve production efficiency and product quality. Through advanced automation equipment, the line realizes high-precision component assembly, ensuring that every link can be carried out in strict accordance with the specification. At the same time, the system integrates a comprehensive test function, which can monitor the performance indicators of the product in real time, to ensure that each machine system has passed strict quality inspection before leaving the factory.

Underlying Parameter

| Working pressure (M Pa) | 0.4~0.6 |

| Size(mm) | L20000*W6000*H1900 |

| Control System | PC、PLC、MES |

| UPH | 60 |

| Yield(%) | ≥99.0% |

| Operation rate (%) | ≥98.0% |

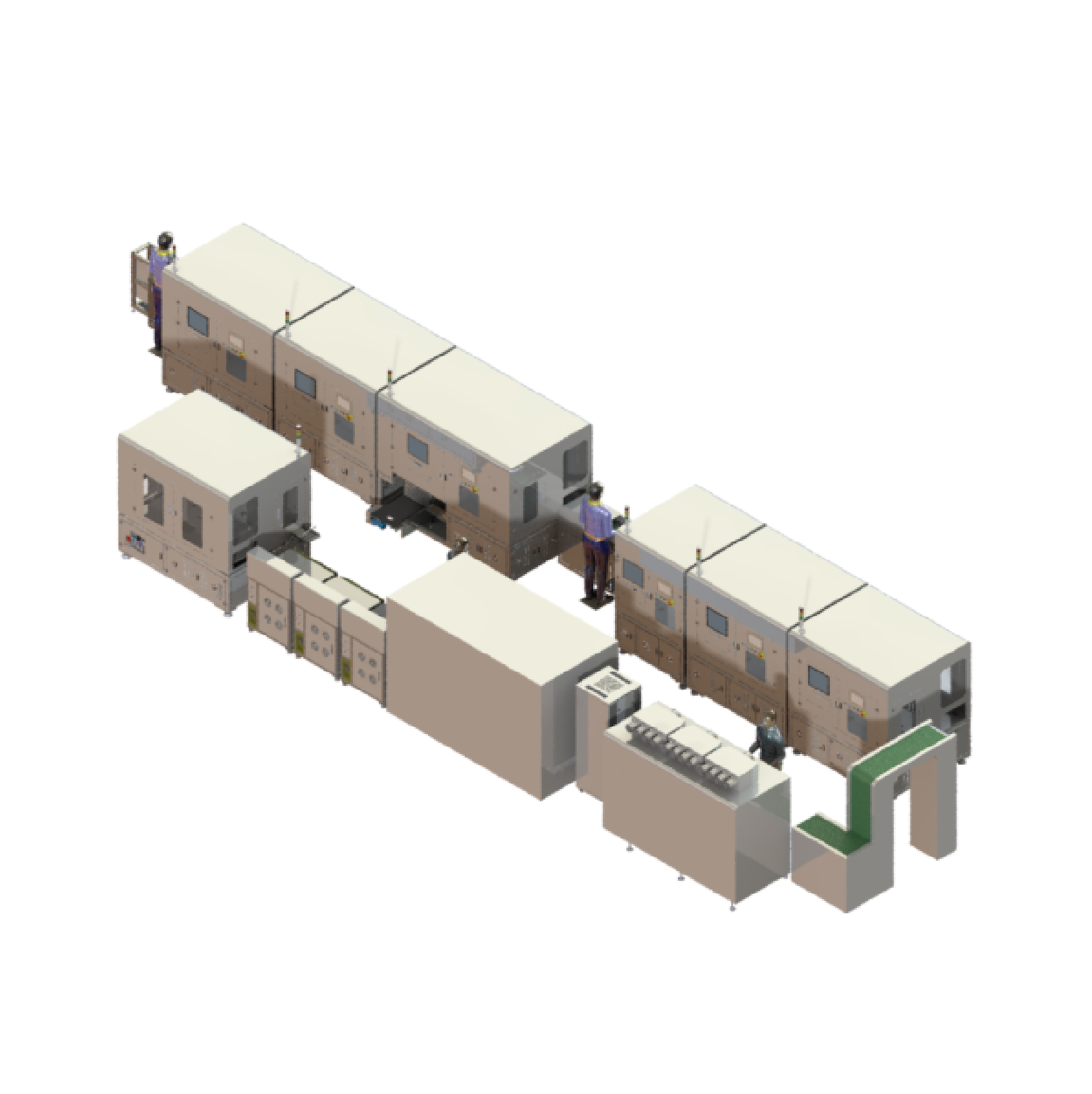

Engine system B assembly test line

The B assembly test line is designed to improve production efficiency and product quality, with the dual functions of automatic assembly and comprehensive testing. Through advanced automation technology, the line enables rapid assembly of high-precision components, ensuring that each assembly step complies with strict standards. At the same time, the integrated test system can monitor and evaluate the performance of the product in real time, ensuring that every machine system is subjected to rigorous quality verification before leaving the factory

Underlying Parameter

| Working Air Pressure(M Pa) | 0.4~0.6 |

| Size(mm) | L16000*W4500*H1900 |

| Control System | PC、PLC、MES |

| UPH | 60 |

| Yield(%) | ≥99.0% |

| Operation rate (%) | ≥98.0% |

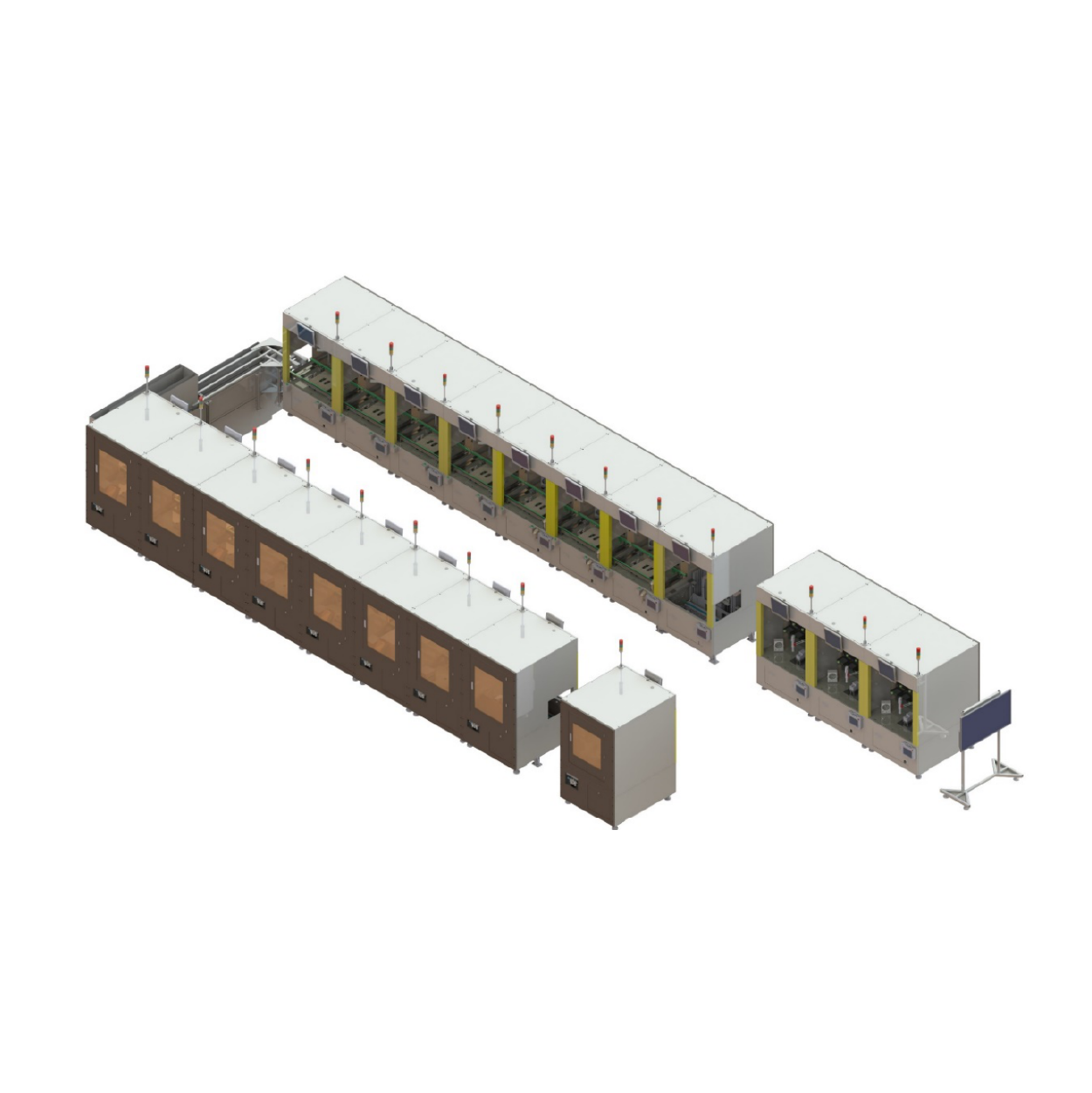

HUD assembly test line

The HUD Assembly test line is designed to improve the productivity and quality of head-up displays (HUDs) with automated assembly and full testing capabilities. The line uses advanced automation technology to achieve rapid assembly of high-precision components, ensuring that each link meets strict quality standards. At the same time, the integrated test system can monitor the HUD’s performance indicators in real time, ensuring that every device is fully inspected before leaving the factory.

Underlying Parameter

| Working Air Pressure(M Pa) | 0.4~0.6 |

| Size(mm) | 16000*5800*1800 |

| Control System | PLC WMS C++ |

| UPH | 60 |

| Yield(%) | ≥99.0% |

| Operation rate (%) | ≥98.0% |

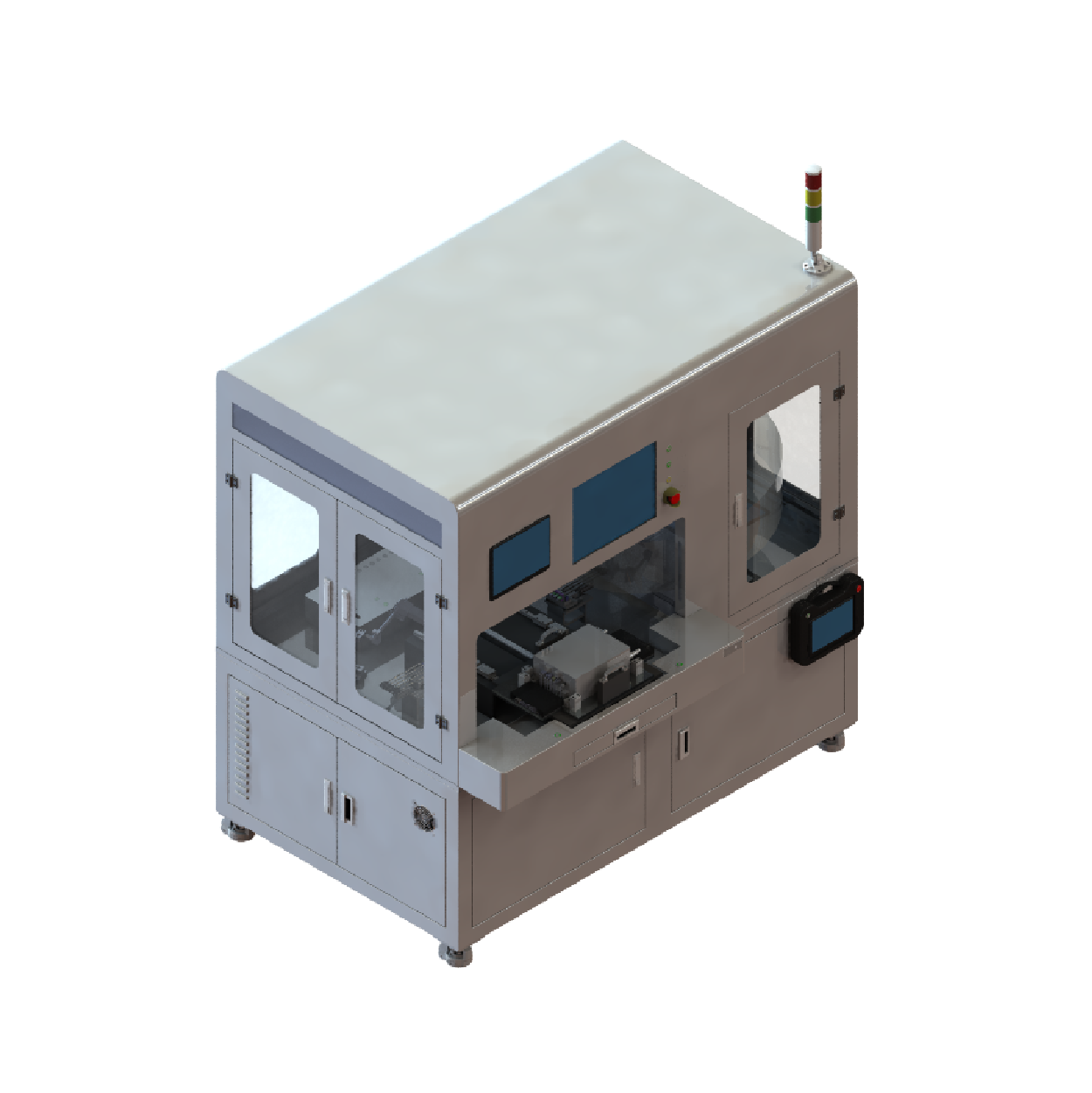

Intelligent cockpit FCT system

The intelligent cabin FCT system uses a copying interface to connect products, supports manual loading and automatic code scanning, and has fast replacement fixtures for compatibility with different products. The system realizes fully automatic test and result storage, supports flexible editing of test recipes, and can be connected to the factory MES system. With data query and analysis function, support Bluetooth and Wi-Fi communication. An integrated vision system for on-screen display inspection, a robotic hand for scribing screen testing, audio electrical signals and current testing in line with industry standards ensure efficient production and excellent quality of the smart cabin.

Underlying Parameter

| Size(mm) | 1800* 1100* 1800 |

| Weight(kg) | |

| Yield(%) | |

| CT | |

| Working Voltage(AC) |

Contact Us

For more information about products and solutions, please leave a message.