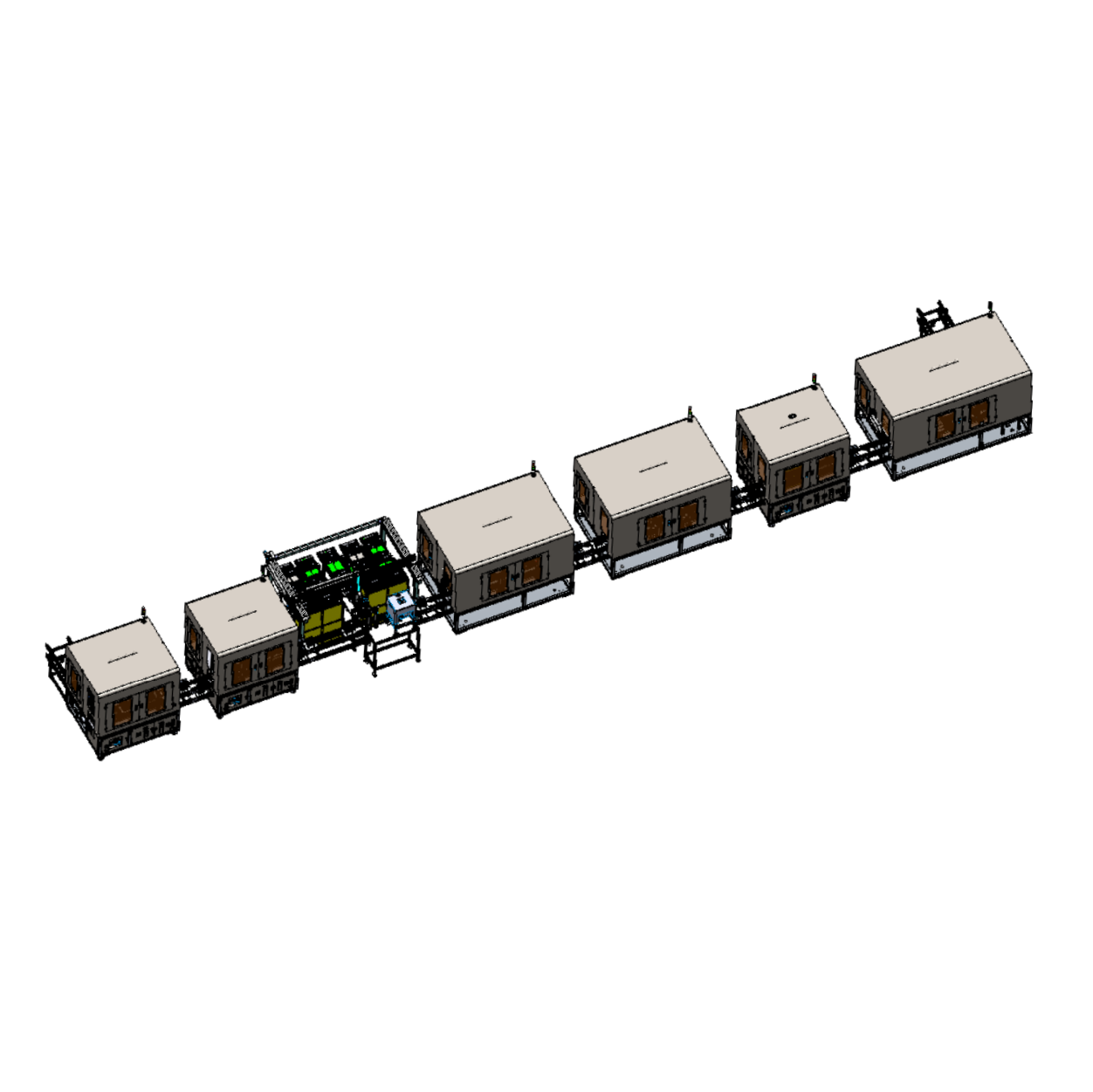

Shel automatic assembly line

The automatic shell assembly line is designed for efficient and accurate shell assembly with a number of automation functions. First of all, the equipment implements automatic dust removal of the shell to ensure clean and dust-free before assembly and improve the quality of subsequent processes. Next, the terminal board, internal and external ground screws, through-core capacitors and solder are automatically installed to ensure that all components are secure and well connected. Through the integrated visual inspection system, the equipment can monitor the installation project in real time to ensure that every link is missing and ensure the integrity of the assembly. After passing the test, the system automatically cuts the material and sends the assembled shell to the next process.

Underlying Parameter

| Working pressure(M Pa) | 0.5~0.7 |

| Size (mm) | 20000×4000×2200 |

| Weight (kg) | / |

| Control system | PLC |

| UPH | 160 |

| Yield(%) | 98 |

| Operating voltage (AC) | 380 |

Contact Us

For more information about products and solutions, please leave a message.