Background

In the context of accelerating digital transformation, smartphones have become an indispensable tool in People’s Daily lives, driving profound changes in the way they communicate, socialize, entertain and work. With the continuous advancement of technology, consumers have put forward higher expectations for the performance, functions and user experience of smartphones. This demand is driving manufacturers to innovate in product design, production processes and supply chain management to stay competitive. However, the fierce market competition and increasingly complex technical requirements make mobile phone manufacturers face many challenges, including production efficiency, cost control and product quality improvement. In this environment, automation technology has emerged as a key factor in improving production capacity and ensuring product consistency.

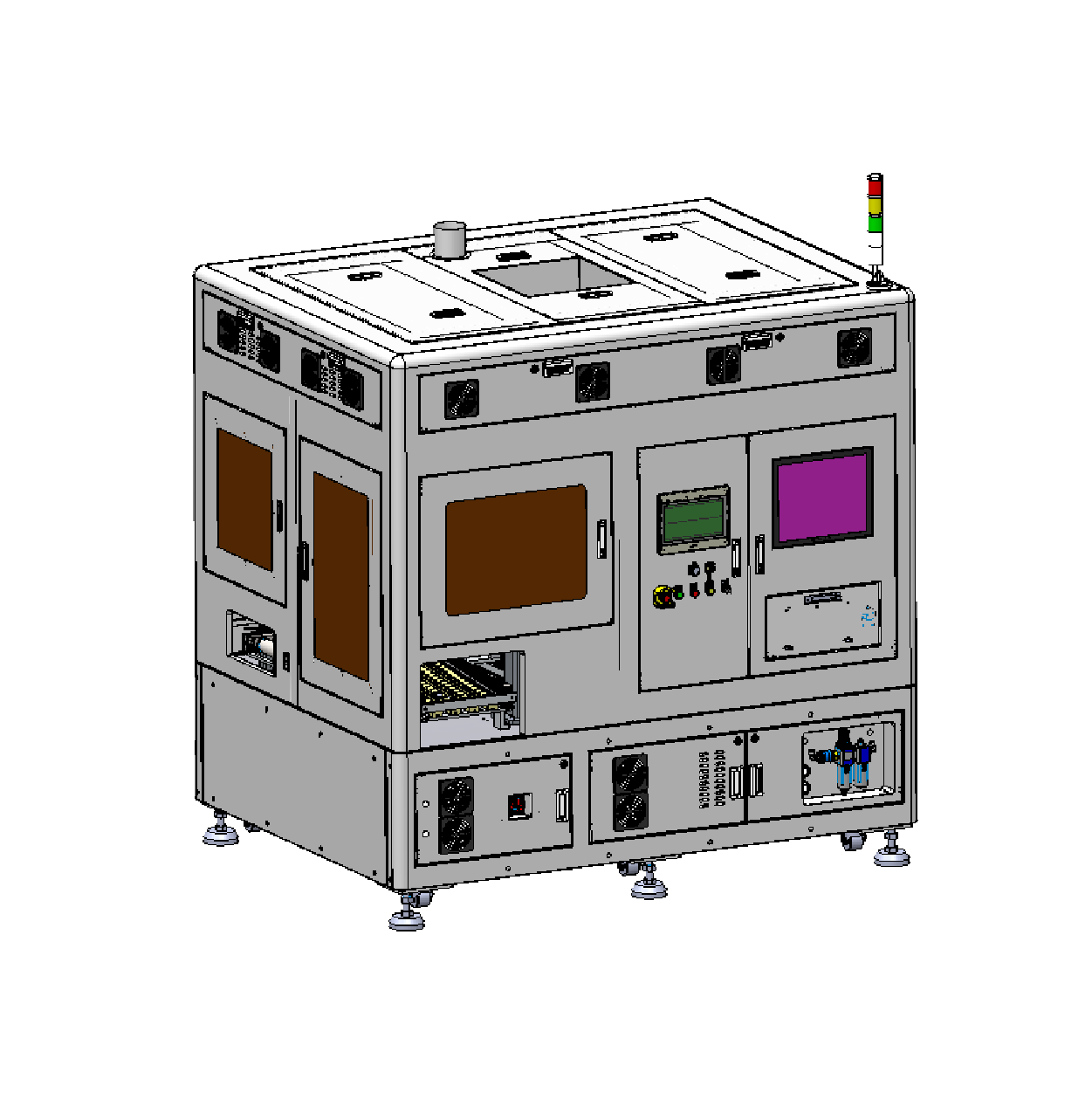

Color box automatic inkjet equipment

The functions of automatic inkjet equipment include automatic loading and unloading and automatic changing, which greatly improves production efficiency and flexibility. The device can automatically activate the surface and perform altimetry to ensure the accuracy and consistency of the inkjet. The inkjet process is combined with UV curing technology to ensure high quality and durability of the printing results. In addition, the equipment is equipped with automatic recheck function, which can monitor the printing quality in real time, and automatically discharge unqualified products, effectively reduce the defective rate, and improve the intelligence and automation level of the production process. Overall, these functions work together to improve production efficiency and product quality, making color box printing more accurate and reliable.

Underlying Parameter

| Working pressure (M Pa) | 0.5 |

| Size(mm) | 2000x1500x2000 |

| Weight(kg) | 800 |

| Control System | PLC |

| UPH | 720 |

| Yield | 99.9 |

| Operation rate (%) | 90 |

| Working Voltage(AC) | 220V |

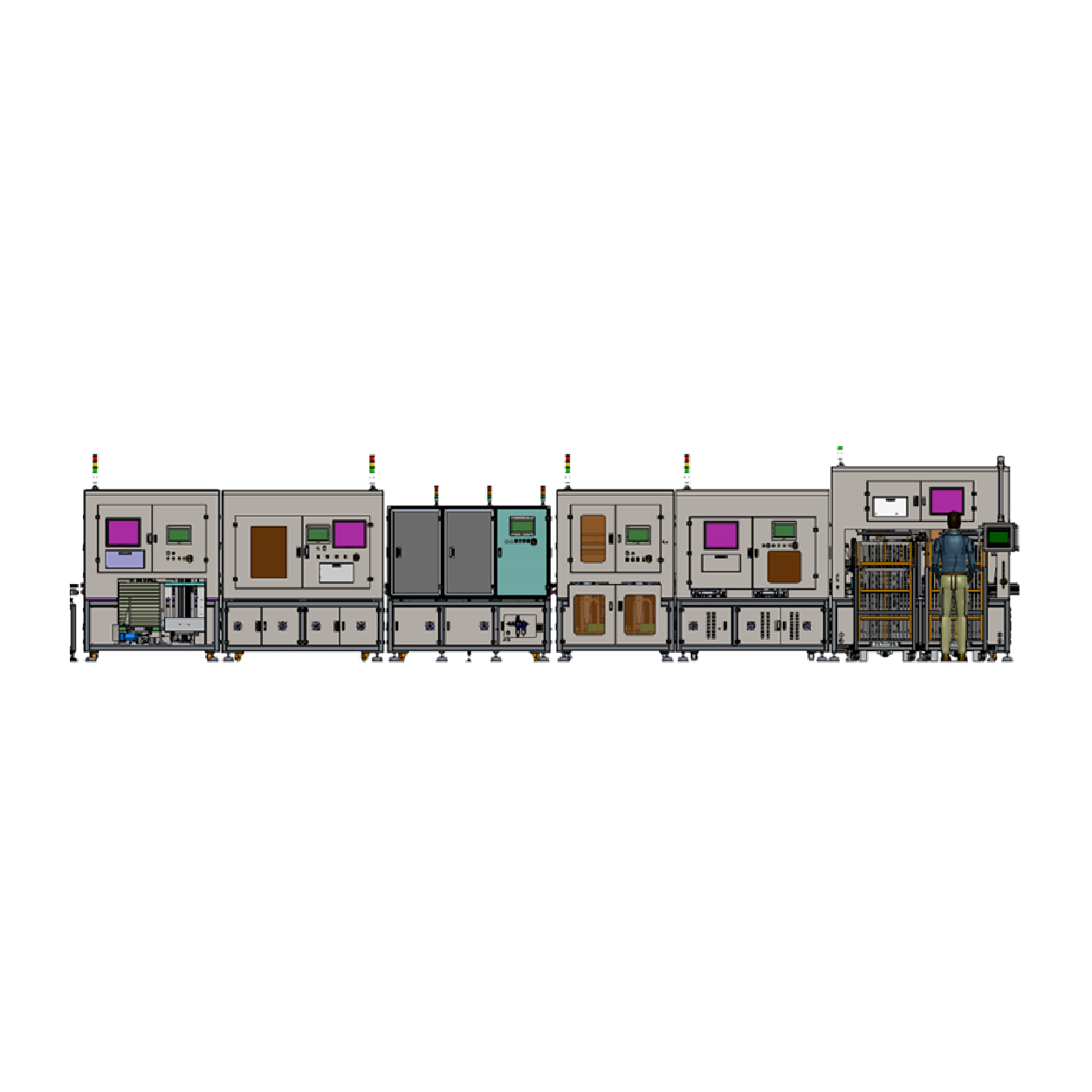

Automatic weighing and scanning equipment

The automatic packaging line has the function of the whole line automation, including automatic feeding and unloading, which greatly improves the production efficiency and operation convenience. All accessories are QR binding and can be uploaded to MES (Manufacturing Execution System) in real time, ensuring data transparency and traceability at every step. In addition, the automatic packaging line supports non-stop materials, and can flexibly adapt to a variety of color box types to meet the packaging needs of different products. These advanced functions not only improve the flexibility and continuity of the production line, but also enhance the intelligent level of the overall production management, providing enterprises with efficient and reliable packaging solutions.

Underlying Parameter

| Working Air Pressure(M Pa) | 0.5 |

| Size(mm) | 10800x2300x2000 |

| Number of machines | 6 |

| Control System | PC |

| UPH | 600 |

| Yield(%) | 98 |

| Operation rate (%) | 85 |

| Working Voltage(AC) | 220V |

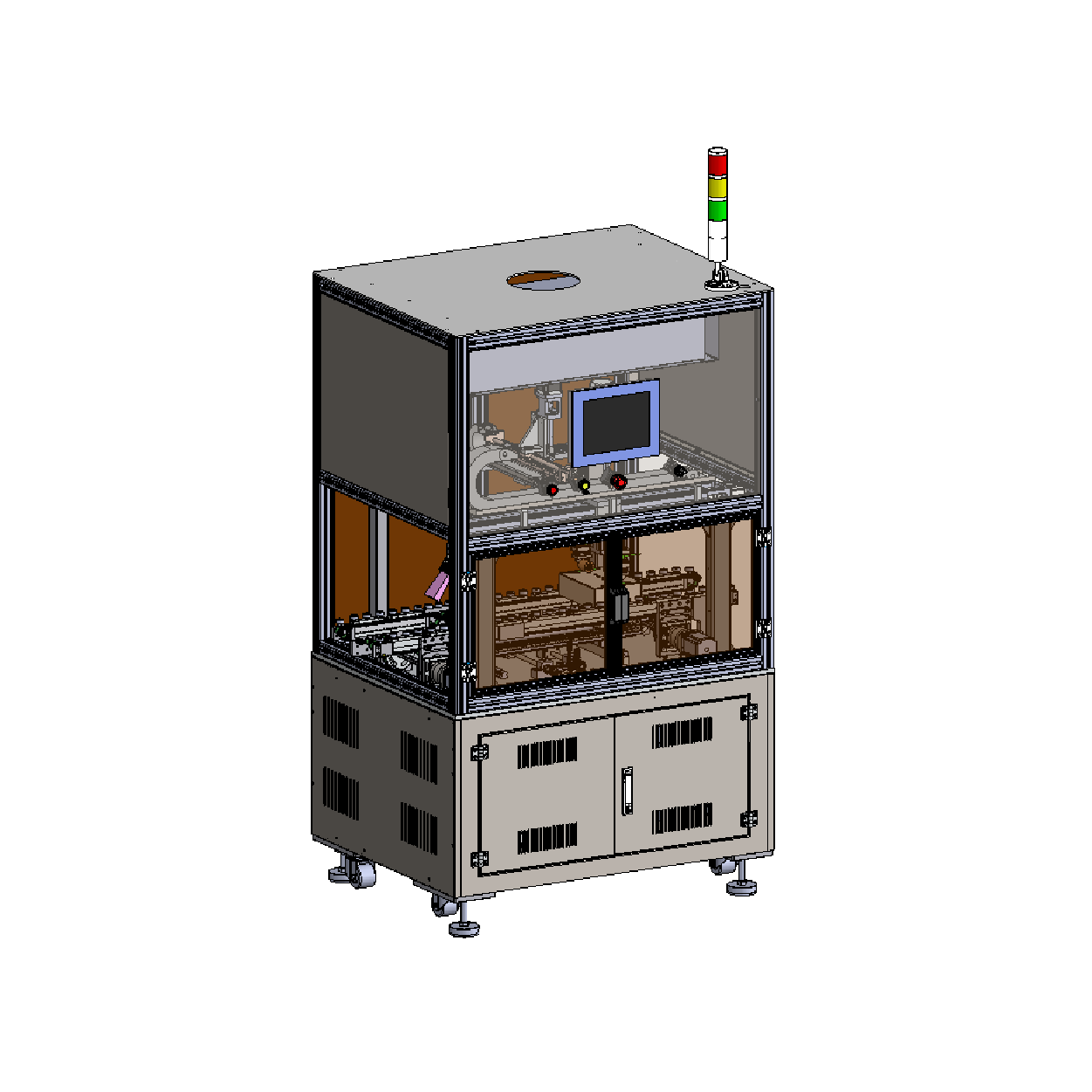

Automatic rolling equipment

The automatic rolling machine is designed to increase production efficiency, with the function of automatically rolling the product seal, ensuring the tightness and consistency of each seal. The equipment is also equipped with automatic code scanning function, which can quickly identify and record product information, simplifying the material management and tracking process. In addition, the internal flow line design of the equipment realizes automatic pitch change to adapt to the needs of different product specifications, further improving the flexibility and efficiency of the production line. Together, these innovative features build an efficient and intelligent production environment that gives companies an edge over the competition.

Underlying Parameter

| Working Air Pressure(M Pa) | 0.6 |

| Size(mm) | 1200x780x1850 |

| Weight(kg) | 500 |

| Control System | PLC |

| UPH | 418 |

| Yield(%) | 99.9 |

| Operation rate (%) | 95 |

| Working Voltage(AC) | 220V |

Contact Us

For more information about products and solutions, please leave a message.